Three ways to cut Europe’s heating bill

Heat. It’s the single largest energy use in the world.

Heating water, our homes and industrial processes accounts for more than half of all energy demand globally. Just over half of the heat produced is used in industry – most of the rest goes on heating water, homes and buildings.

Only 10% of this heat is generated from renewable sources, which means that it has a huge carbon footprint – 40% of global CO2 emissions – that needs to be tackled urgently.

And while all forms of heating have come under scrutiny, industrial heat presents the biggest challenge for decarbonisation by far.

Here are three approaches that could help defuse the impact of industrial heat on our planet.

1. Waste heat recovery

Europe wastes so much heat that, if recovered, it could deliver the equivalent of Europe’s total heat demand for buildings. This is based on the findings of a Danish pilot project aimed at proving Copenhagen’s ability to be carbon-neutral by 2025.

The solution could be a smart thermal grid across Europe that would harvest waste heat from sources as diverse as power plants, data centres and industrial settings.

Initially part of the EU’s Pitagoras project, ORI Martin’s steel plant in Brescia, Italy, started converting waste heat in early 2016, generating electricity and providing district heating during the winter months.

Heat that would normally be left to disperse into the atmosphere through exhaust gasses is instead channelled into Brescia’s district heating network, warming 2,000 homes. Adding to its direct environmental impact, this approach reduces both the cost of heating and electricity, as well as cutting down use of electricity from the local, fossil-fuelled power station. It also drastically reduces the total amount of water previously used to cool down the industrial process, thanks to the introduction of the waste heat recovery system, replacing the traditional water-based quench tower.

Similar industrial-scale projects are underway around Europe and the world, converting waste heat from steel, cement and glass manufacturing into power.

With the underlying technology now mature, policy support is needed to interconnect these sources to cover a wider area and to instigate new projects around the continent.

2. Heat pumps

Heat pumps have long been a staple energy source in countries like Japan, where they have been used for domestic water heating since the mid-1980s, thanks to Japan’s commitment to greener heating.

Heat pumps take natural warmth from the ground or air, for example, convert it and use it for domestic and industrial heating, with an overall efficiency exceeding alternative fossil-fuel-based systems.

While they currently meet just 5% of global heat demand from residential buildings, sales have been expanding quickly in recent years, including in Europe.

The technology also holds significant potential for the electrification of heat in a decarbonised power grid – for example in district heating – and some energy-intensive industrial processes. Large, utility-scale heat pumps can generate high levels of heat using renewable electricity, providing another alternative to the use of fossil fuels.

The International Energy Agency (IEA) has highlighted that large-scale heat pumps face market design barriers. This is because many energy markets are still based on the traditional concept of dispatchable energy and traditional power generation and trading.

Like other no-carbon or low-carbon approaches, such as hydrogen, the adoption of large heat pumps will need policymakers to step in. This could come in the form of either removing surcharge costs on electricity for heat pumps targeting the decarbonisation of heat, or by tightening up carbon pricing.

3. Cogeneration

Many industrial processes require a high degree of steam and electricity. Rather than generating them separately, cogeneration can create significant efficiencies.

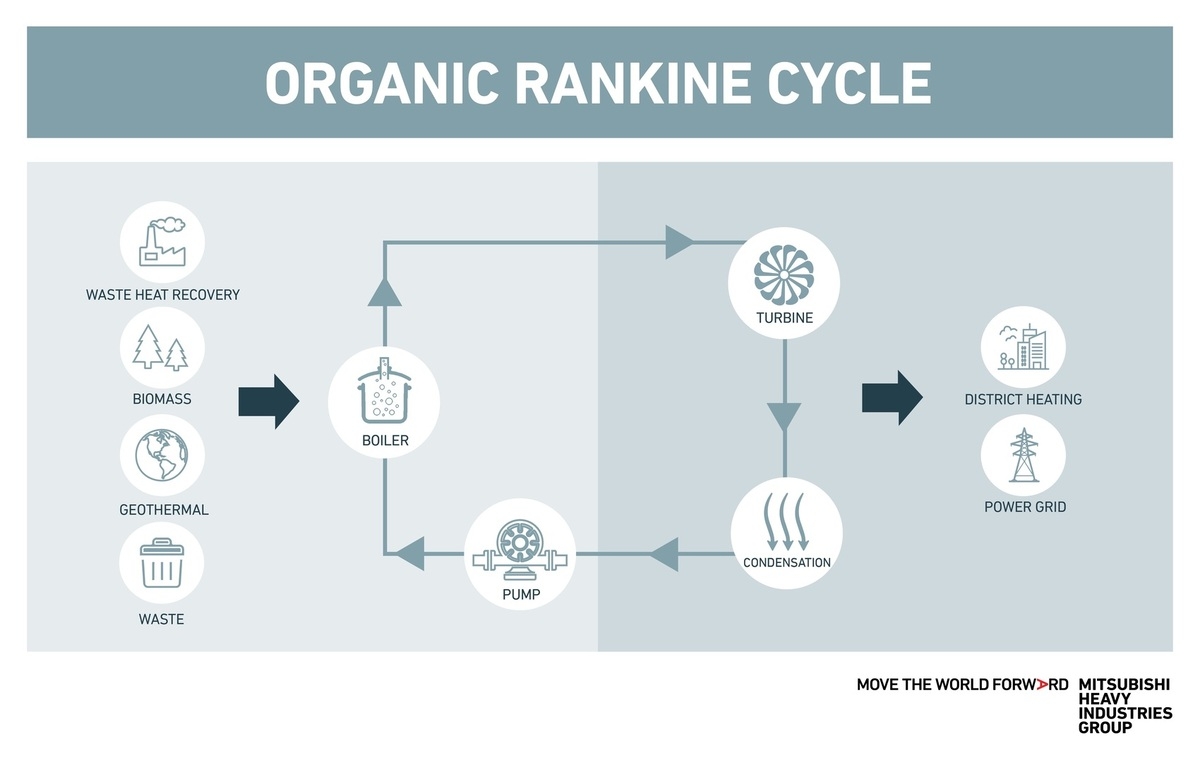

For example, Organic Rankine Cycle (ORC) technology can generate electricity and steam together − typically with a conversion rate of above 90% − from a range of sources including biomass or heat generated on-site.

The greater efficiency of this combined process and similar processes means less fuel and fewer emissions.

For example, Turboden, part of Mitsubishi Heavy Industry (MHI) Group, is building an ORC cogeneration plant for the Centrale del Latte di Brescia in northern Italy. It will provide electricity and steam for milk pasteurisation, replacing traditional gas-fired boilers.

And just inland from Venice, Cereal Docks uses a similar cogeneration system to extract and refine oil from a range of seeds such as sunflower, rapeseed and soy for use in the food industry. This innovative system makes it possible for the customer to cogenerate 100% of its power and steam demand.

There is a wide range of applications for cogeneration of steam and electricity, ranging from chemicals and pharmaceuticals to textiles and paper.

Scaling up innovative solutions for industrial use

All three solutions are highly developed and deliver low-carbon or no-carbon heat and power on an industrial scale in many settings. They have gone beyond experimentation and have a track record of lowering the impact of industrial heat and power on our environment.

Reaching net-zero carbon emissions by 2050 sets us a tight deadline, and no single solution will get us there on its own. We need regulators and policymakers in Europe – and beyond – to help accelerate the industrial energy transition.

Changes to market structure, subsidies, reviewing surcharge costs allocation and carbon pricing are only some of the mix of incentives that would help with scaling up the use of cogeneration, heat pumps and waste heat recovery.

Discover more about Turboden’s ORC technology