The colors of hydrogen: Expanding ways of decarbonization

The color green has become synonymous with nature and everything that is good for our planet: energy-efficient household appliances, sustainably made products, low-carbon energy and even investments.

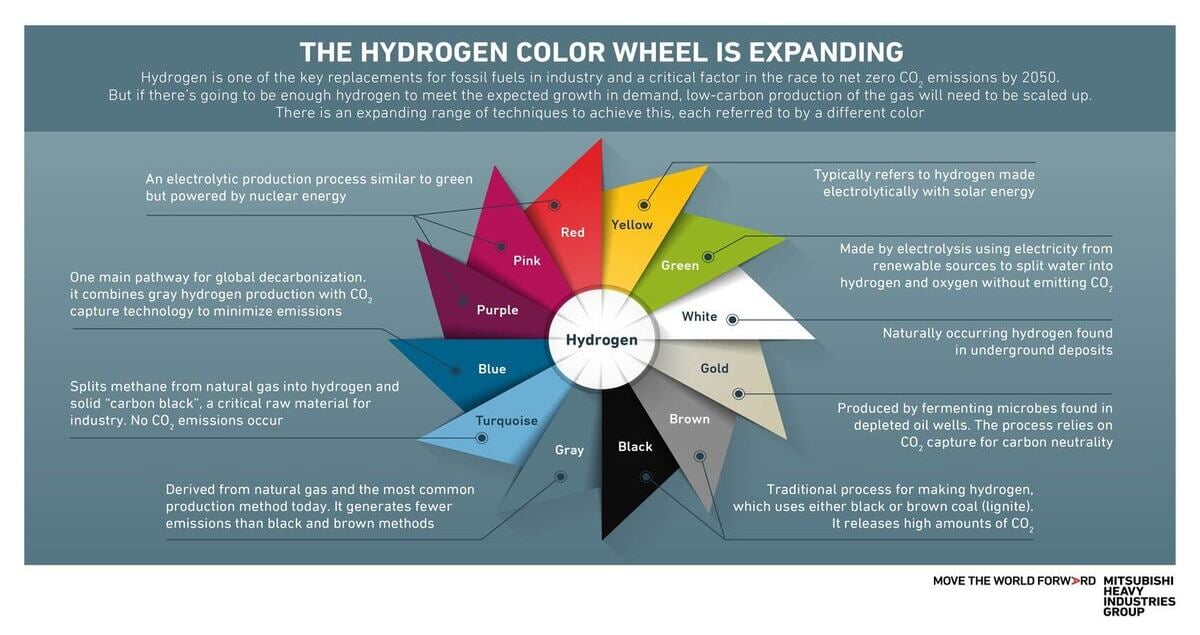

It’s also used to describe hydrogen that’s produced without greenhouse gas emissions — something that’s critical to the global energy transition. But generating enough hydrogen to match a potential 100% rise in demand by 2030 will require multiple production methods, not just green, but blue, yellow, pink, turquoise — a rainbow.

This kaleidoscope of color codes helps differentiate between the various production methods. Here’s a roundup up of what each one means:

The most common colors of hydrogen

Black and brown hydrogen

Black and brown hydrogen represent the traditional process for making hydrogen, which uses either black or brown coal (lignite). The method releases high amounts of CO2 and carbon monoxide into the atmosphere. In 2020, around a fifth of hydrogen was still made using coal, according to the International Energy Agency (IEA).

Gray hydrogen

Gray hydrogen is derived from natural gas. It is the most common production method today, with nearly 60% of hydrogen made in this way, the IEA says. Gray hydrogen generates significantly lower CO2 emissions than the black and brown versions.

Blue hydrogen

Blue hydrogen involves steam reforming of natural gas (as with gray hydrogen) but then capturing the resulting CO2 emissions. This carbon dioxide can then be either stored or used in industrial applications that need it as a feedstock. Blue hydrogen is one of the main pathways for global decarbonization strategies as it can produce low-carbon hydrogen at scale.

Green hydrogen

Green hydrogen is the holy grail for policymakers, climate activists and the energy sector. It is made by electrolysis --- a process that uses electricity to split water into hydrogen and oxygen --- and the electricity must be provided by renewable energy, such as solar or wind. While production volumes are still low and the costs are high, around 350 projects are underway globally that could shift these economics.

Innovation in hydrogen production

Yellow hydrogen

Yellow hydrogen typically refers to hydrogen made using electrolysis powered by solar energy. However, it is sometimes also used to describe electrolyzed hydrogen created from a mix of renewables and fossil fuel power.

Pink hydrogen

Pink hydrogen production is similar to green but with one difference: the electrolysis is powered not by renewable electricity but by nuclear energy, which is experiencing a revival as a carbon-free energy source]. The first commercial deal was signed in January 2022 and will see a Swedish nuclear power plant deliver pink hydrogen to industrial gas giant Linde. Hydrogen production using nuclear power is also sometimes referred to as purple or red hydrogen.

Turquoise hydrogen

Turquoise hydrogen gets its name because its production process sits somewhere between green and blue. A method called methane pyrolysis splits methane from natural gas into hydrogen and solid carbon, also known as "carbon black". The latter is a critical raw material with a wide variety of industrial applications, including making car tires, coatings and batteries. Methane splitting is not a new concept, and a few commercial-scale plants already exist. The great advantage of the technology is that there are no CO2 emissions to deal with.

White hydrogen

White hydrogen is naturally occurring hydrogen found in underground deposits. In recent years, scientists have found that more deposits exist than previously thought. These can often be accessed relatively easily by drilling a well. One well in Mali has been actively delivering hydrogen since 2012. Exploratory projects are underway in Brazil, Australia and other parts of the world. Science Business --- a network of universities, companies, and research and policy organizations --- estimates that natural hydrogen may be even cheaper to produce than gray hydrogen, at under $1/kg. While white hydrogen is a carbon-free fuel, the environmental impact of the extraction methods must be considered.

Gold hydrogen

Gold hydrogen is another term sometimes used to describe naturally occurring hydrogen, as well as hydrogen produced by fermenting microbes found in depleted oil wells. It not only offers another low-cost pathway for hydrogen, but also extends the life of oil fields rather than leaving them as stranded assets. The production and extraction process for gold hydrogen does, however, rely on CO2 capture for carbon neutrality.

Many countries' plans to decarbonize rely on developing much greater use of hydrogen. The IEA says "hydrogen and hydrogen-based fuels will need to fill the gaps where electricity cannot easily or economically replace fossil fuels".

While fossil fuel-derived hydrogen still dominates current supply, the biggest challenge for the next decade will be rapidly scaling up the rainbow of low-carbon production. This will be critical to creating a steady supply and demand cycle in line with net zero ambitions. Policymakers, producers, technology companies and users must collaborate to generate this virtuous — and colorful — circle.

Get our free eBook on Hydrogen and ammonia: Rocket fuel toward net zero by 2050