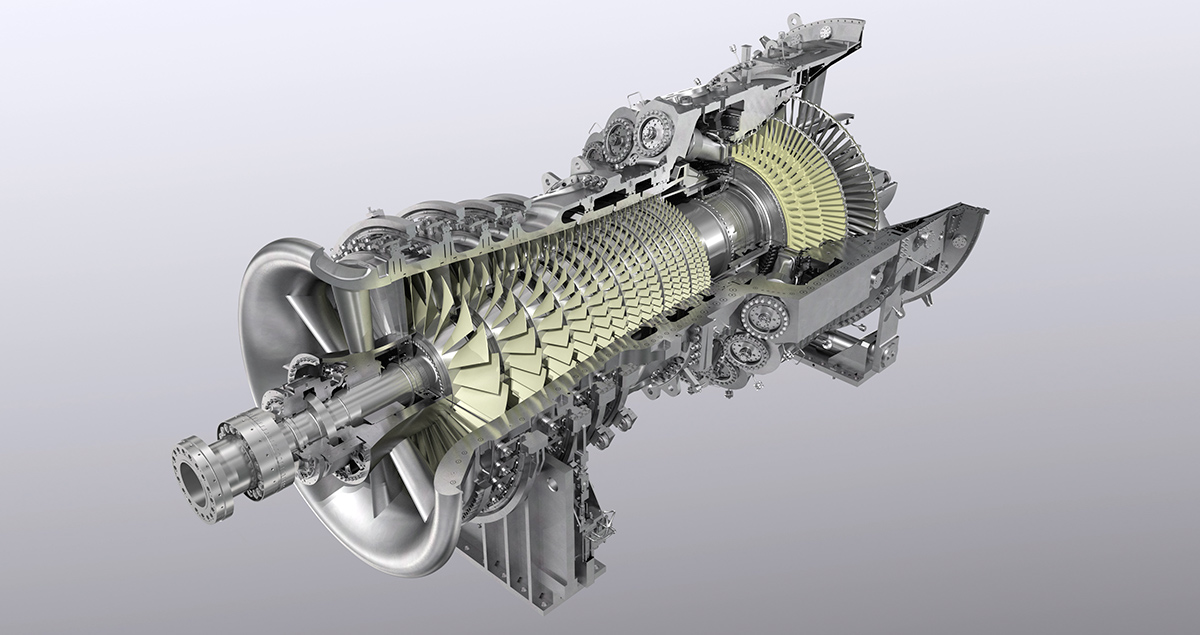

Powering the Energy Transition with MHI’s advanced gas turbines

This article was previously published in our newsletter, if you're not already a subscriber, sign up here.

In a world trying to balance growing demands for power with a need to reduce carbon dioxide emissions, while also ensuring secure supplies of energy, natural gas has a vital role to play. It is cleaner than coal or oil and provides more stable and flexible electricity than renewables. That makes natural gas one of the keys to a successful global Energy Transition.

This is reflected in the scenarios outlined by the International Energy Agency: while the contribution from coal and renewables varies significantly between its pessimistic and optimistic outlooks, the agency forecasts that natural gas will supply a steady 16-18% of world electricity demand until at least 2030 (compared to 22% in 2022).

Facing real-world challenges

Policymakers are, increasingly, coming to terms with this reality. Hopes that the world could be powered entirely by renewables within a few years are starting to fade due to concerns about their ability to supply stable electricity. At the same time, the European Union, the world’s strictest climate regulator, has declared natural gas as ‘important’ for the transition to Carbon Neutrality.

Meanwhile, our customers, from utilities to industrial manufacturers, are responding to market forces. To meet growing energy demand, from sources like data centers, they recognize the need to diversify beyond renewable energy alone. Gas-fired power plants that can utilize hydrogen and ammonia fuels can often be the solution.

All of this translates into strong demand for gas turbines. Latest gas turbine combined cycle (GTCC) power plants emit 65% less CO₂ than traditional coal-fired boilers. Most emissions can be removed by then also installing carbon capture technology. And fully eliminated once the turbines switch to firing hydrogen (or ammonia), which emits no CO2 during combustion, rather than natural gas. This should translate into continued annual worldwide demand of some 40-50 Gigawatts of new gas turbines over the next three to four years – and further steady demand beyond that.

Developing leading solutions

Rapid advances in hydrogen co-firing technology will underpin this growth. It is relatively simple to adapt gas turbines to decarbonized fuels – developing a new type of combustor is the key – and at Mitsubishi Heavy Industries we expect our large frame turbines to achieve “CO₂ Zero” by using 100% hydrogen fuel after 2030. We have started testing our middle- and small-size turbines at 100% at our Takasago Machinery Works.

Takasago, the integrated facility in western Japan is one of the secrets to our success and MHI has invested steadily over many years to turn this giant facility into a center of excellence. This is the only factory in the world where gas turbines are researched, designed, manufactured and verified on the same site.

The result is a product range that is as good as anything else on the market in terms of capacity and efficiency and, our customers tell us, better in other critical respects.

In terms of reliability, our latest JAC turbines achieve 99.5% worldwide after extensive verification – at Takasago, we will run a new or an improved model for a whole year at our T-Point 2 test facility, where it is connected to the local electricity grid, producing power for local homes and businesses. Only once verified, will we start to market it.

Takasago is also where we are pushing the frontier of decarbonization and working on the early commercialization of hydrogen-compatible gas turbines. MHI has worked with hydrogen for many years in our Space business. At the newly built Takasago Hydrogen Park, we are now producing our own hydrogen to demonstrate co-firing and 100% firing of actual gas turbines.

Finally, there is our after-sales service. Most customers choose to enter into Long-Term Service Agreements with us that last 15 or even 20 years. If an issue emerges, we promise to fly out an engineering team, while our real-time TOMONI monitoring system anticipates problems, ensuring stable plant operation and preventive maintenance.

All of this tends to make our turbines more predictable and profitable to run over a typical 20-year lifespan. But customers value not only the favorable economics but the high service levels, the attention to detail and the partnership approach that are key characteristics of Japanese manufacturing.

Expanding engineering excellence

The numbers bear out our approach. In 2022, MHI achieved market leadership and last year we won 46% of the orders for new large gas turbines (those over 100MW). In our 2023 fiscal year, the order intake for our GTCC business amounted to 1,200 billion yen (8.3 billion dollars), a record high, and in the first quarter of the current year it has already reached 500 billion yen.

Currently, we are seeing particular strength in the Americas, which tend to account for around a fifth of annual global demand. But we are also strong in Asia and the Middle East, where the switch from coal or oil to gas is at an earlier stage, as well as China.

Beyond gas turbines, we are developing ammonia co-firing technology to decarbonize existing coal-fired power plants, helping many countries, particularly emerging markets, to maintain stable energy supplies. Our Air Quality Control Systems, which remove nitrogen oxides (NOx) and sulfur dioxides (SO₂), play a crucial role when pre-treatment is necessary for CO₂ capture from exhaust gases. And we are excited about the advances in hydrogen production technologies such as SOEC (solid oxide electrolysis cell), that are a more efficient way to producing clean hydrogen than conventional electrolyzers.

The intense focus on decarbonizing human activity is not something I anticipated when I started my engineering career more than 40 years ago. However, I believe companies like MHI are responding to the new challenge with dedication, and the significant investment and intense effort we are putting into developing new technologies and perfecting innovative products will help the world meet its net zero challenge.

![]()

Discover more about 30% hydrogen co-firing at grid-connected T-Point 2