From Sake Brewing to Energy Production

It’s an exciting, albeit confusing and risky age for the energy sector, as researchers turn to new sources for clean, renewable forms of energy. For the layperson, the infrastructures of solar and wind powerare easy to perceive as “clean,” but there are a host of others that come into play, as well as behind-the-scenes infrastructural and energy logistics oriented technologies involved.

Biofuels are one example of the unique synergy that arises when energy developers think “outside the box”. In shifting the focus to fermentation, researchers find themselves relying on sake brewers to produce the biofuels they need. Biofuels, which have existed for as long as automobiles, are now being produced en masse in light of volatile oil prices and global warming concerns. Whereas fossil fuels are developed from decomposed organisms that have been buried for millions of years, biofuels are developed from living or recently deceased organisms through a chemical reaction process that involves fermentation and heat to break down molecules in the plants. Much work is being done today on sustainably sourcing biofuels in a way that is both cost and energy efficient. Sake brewers are joining efforts with energy companies and researchers to drive those efforts.

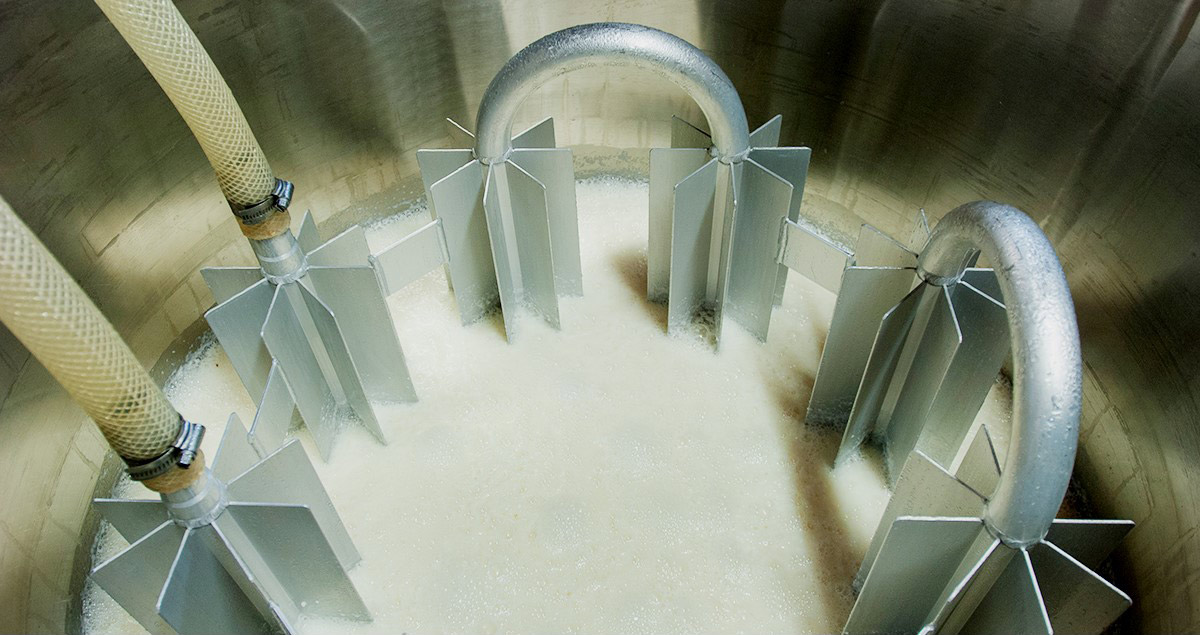

Mitsubishi Heavy Industries (MHI) is one of the companies that has made successful strides in using sake brewing technology to produce biofuels. In 2011 they successfully completed a three-year endeavor to develop biofuel ethanol from locally sourced soft cellulose, such as rice and barley straw, with the help of Hakutsuru Sake Brewing in the fermentation process and Kansai Chemical Engineering in the distillation and dehydration processes. Hakutsuru Sake Brewing teamed up with Kobe University to establish a technology that converts sugar in rice and barley to ethanol through the use of yeasts. The yeasts are selected from those in use or those bred with non-genetically modified organismal (Non-GMO) technology. The project’s success reflects an efficient use of unused biomass at a low cost (below 90 yen per liter) to produce a more sustainable energy source to fossil fuels. MHI’s project directly addresses a major concern of biofuels: that The conventional process of growing crops, making fertilizers, and extracting ethanol from corn, palm oil, or sugarcane consumes too much energy for it to be efficient. MHI’s biofuel production utilizes cellulose instead of unsustainable crops, and thus requires less energy to produce, emitting less carbon dioxide in the process. This is made possible because of that special yeast fermentation process.

Biofuels reflect a fascinating synergy between the ancient craft of sake production and the research efforts being made today to source alternative fuels. They will only continue to gain in popularity as they become a cheaper, more efficient source of energy that leaves a smaller carbon footprint in the process. Looking to more unconventional places, such as sake breweries, for innovation in developing sustainable energy opens a host of new potential for the future.