4 ways of storing hydrogen from renewable energy

This article was originally published on 26 June 2020 and updated on 30 November 2022

Few chemicals carry as much hope and aspiration as hydrogen. Over the last few years, the first element in the periodic table has gone from a global buzzword to one of the most promising routes to decarbonizing industry, power generation and transport.

As production of the gas using low-carbon resources ramps up around the globe, the vision of a green hydrogen-powered economy faces a number of challenges. Alongside scaling production and lowering costs, one of the biggest challenges is hydrogen storage.

Why is hydrogen energy storage vital?

Hydrogen has the potential to address two major challenges in the global drive to achieve net zero emissions by 2050. First, it can help tackle the perennial issue of the intermittency of renewable energy sources such as wind and solar. By converting excess power generated on windy or sunny days into hydrogen, the gas can store renewable energy that can then be dispatched at times of peak demand as a clean fuel source for power generation. Second, hydrogen can replace fossil fuels to decarbonize sectors where electrification alone won’t suffice, such as domestic heating, industry, shipping and aviation.

The hitch is that, while an excellent medium for renewable energy storage, hydrogen itself is hard to store.

This is because it has a low volumetric energy density compared to other gases — such as natural gas — meaning it takes up significantly more space. Also, hydrogen has a boiling point close to absolute zero and requires cryogenic storage. And while it does not typically corrode storage containers, it can cause cracks in metals under certain conditions.

Here are four hydrogen storage solutions that could help address these challenges, as mapped out by Hydrogen Europe.

4 ways of storing renewable hydrogen

1. Geological hydrogen storage

One of the world’s largest renewable energy storage hubs, the Advanced Clean Energy Storage Hub, is currently under construction in Utah in the US. This hub will bring together green hydrogen production, storage and distribution to demonstrate technologies essential for a future decarbonized power grid.

Mitsubishi Power, a power solutions brand of Mitsubishi Heavy Industries (MHI), is providing the technology for producing hydrogen from renewable energy, which will then be stored in a series of salt caverns. They will be constructed deep underground in a salt dome that covers more than 4,800 acres. Each cavern will be about 67 meters in diameter and 580 meters in height.

Mitsubishi Power is also involved in a similar project with Texas Brine in the US, where salt is being extracted from giant caverns to make room for hydrogen storage.

Gas storage in salt caverns is an established method, enabling easy knowledge transfer. Other options for geological storage include depleted oil fields and aquifers.

2. Liquified hydrogen

As well as storing hydrogen in its gaseous state, it can also be stored as a liquid. MHI Group, along with the space industry as a whole, has used liquefied hydrogen to fuel rockets for many years.

But liquid hydrogen storage is technically complex and, as such, has historically been very costly.

Hydrogen has to be cooled to -253°C and stored in insulated tanks to maintain this low temperature and minimize evaporation. This requires a complex plant.

Complexity and cost have limited the use of liquified hydrogen to date. Some of the biggest users include the semiconductor chip industry and the application hydrogen is probably best known for: as rocket fuel for space launches.

The International Energy Agency highlighted in its most recent hydrogen report that critical technologies such as liquefaction still needed to be scaled up. It pointed to the launch of the first shipment of liquefied hydrogen between Australia and Japan in early 2022 as a major milestone.

With the proliferation of renewable hydrogen supply and demand, greater economies of scale will make liquefaction a more viable storage and transport option.

3. Compressed hydrogen storage

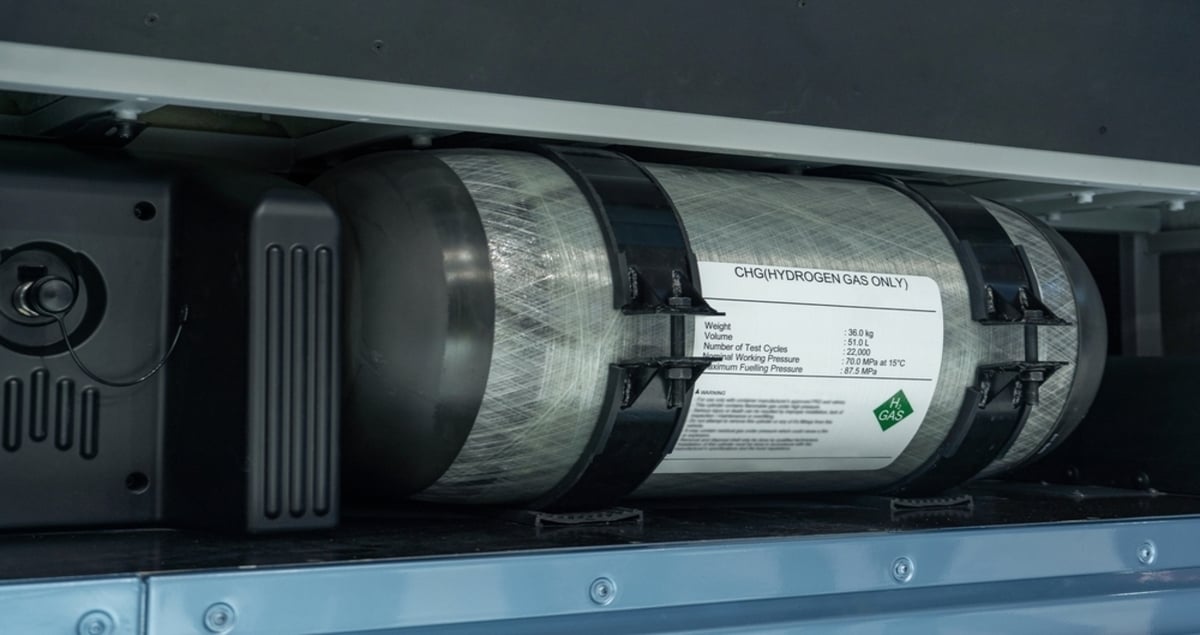

Like any gas, hydrogen can also be compressed and stored in tanks, and then used as needed. However, the volume of hydrogen is much larger than that of other hydrocarbons — nearly four times as much as natural gas. For practical handling purposes, hydrogen therefore needs to be compressed. For example, fuel-cell powered cars run on compressed hydrogen contained in large, highly pressurized containers.

If an application requires hydrogen volume to be reduced further than compression can achieve, it can be liquefied. The two techniques — compression and liquefaction — can also be combined.

Hydrogen’s low energy density, high volume and need for cryogenic storage are some of the biggest barriers to its growth. This is especially true for mobility applications such as heavy transport, where the space and other requirements for hydrogen storage would drastically reduce the room for passengers and cargo. The same applies to vehicles, where a balance needs to be struck between passenger space and range.

One solution is a new type of tank for the automotive sector — one of many hydrogen infrastructure projects supported by the European Union.

4. Materials-based storage

An alternative to compressed and liquefied hydrogen is materials-based storage. Here, solids and liquids that are chemically able to absorb or react with hydrogen are used to bind it. This includes creating metal hydrides from elements such as palladium — which can absorb 900 times its own volume in hydrogen — as well as magnesium, aluminum and certain alloys.

Using ammonia — a compound of hydrogen and nitrogen — as a carrier for hydrogen is, arguably, the option with the most potential. Its energy density by volume is nearly double that of liquefied hydrogen, making it far easier to store and transport.

This means that hydrogen is converted to ammonia, transported to its destination and then “cracked” to release the hydrogen at its point of use. Ammonia cracking is still in the early development stage and conversion rates remain low — around a third at best.

It has been suggested that ammonia could become the “workhorse” of a future hydrogen society, especially where direct use of hydrogen is not an option. Countries such as Japan and South Korea are looking to import ammonia as they have less opportunity to produce hydrogen and get it to direct offtakers. For example, MHI’s shipbuilding division is designing a vessel that will be powered by and also ship ammonia.

Most countries in Europe and the US are more likely to prioritize hydrogen as it can be more easily produced and consumed locally, such as within industrial clusters or via pipelines.

Of the more than 100 low-carbon hydrogen projects listed in Wood Mackenzie’s Hydrogen Project Tracker, over 85% integrate ammonia and hydrogen to serve domestic and export markets.

Is hydrogen safe?

Safety is an important issue when it comes to low-carbon fuels, especially when they may be stored, transported or used in settings where the public could be exposed to them.

Hydrogen is non-toxic and dissipates quickly because it’s lighter than air. However, there are still risks to consider.

When combined with air and in sufficient concentration, hydrogen can be flammable. Ventilation and leak detection are therefore vital wherever hydrogen is stored and used. Special detectors are required as hydrogen burns with a nearly invisible flame. Storage containers need to be strong enough to withstand embrittlement, which can cause cracks in some materials.

All these steps will ensure that hydrogen remains a safe fuel for the future.

Where next for hydrogen storage?

It’s clear that unleashing hydrogen’s potential for delivering truly decarbonized societies and economies will depend on identifying the most suitable storage method for each application. And it’s not only about the technical possibilities — any approach has to be economically viable.

But science does not stand still: scientists at Lancaster University in the UK have discovered a new material that can store four times more hydrogen in the same volume as current fuel cell technologies. It also doesn’t require external heating and cooling. While the research focus was on hydrogen-fueled cars, the implications of this discovery may ultimately go further to help open up a mass market for hydrogen.

Discover more at MHI’s latest whitepaper: Hydrogen and Ammonia